Share this

Electrical Control Panel Components – Each Part Explained

by Simcona on Mar 12, 2025 2:21:00 PM

To make a successful product, machines need more than simple might.

On any good production line, the equipment and its operators rely on control panels to provide protection, power, and data. And on any good production line, the panels rely on an army of components big and small to keep the panel running smoothly.

A well-designed control device reduces downtime while improving safety for human and machine alike. To maximize your manufacturing floor’s potential, it’s time to learn the key components of an electrical control panel:

What’s in an Electrical Control Panel?

A control panel is a box that contains electrical components required to run a factory machine or process. A typical industrial control panel component list includes:

- Breakers, suppressors, & fuses

- Power distribution

- Power supply

- Communications

- Motor drives

- Terminal blocks

- Relays & contactors

- HMI

- Transformer

- Wire duct & DIN rail

- Enclosure, backplate, & grounding panels

The control panel also goes by the name of PLC panel, with PLC short for programmable logic controller. This means the PLC is basically an industrial-grade computer, and that high voltage and high stakes are at play with many of these components.

Part-by-Part Electronic Control Panel Component Overview

No two applications and environments are identical, but here’s what you can expect to see in an electrical control panel.

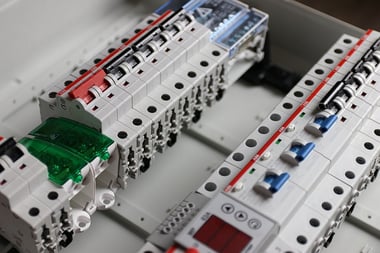

Circuit Breakers, Surge Suppressors, & Fuses

- What? Components that detect excess electrical flow and open or break the connection to stop the current.

- Why? To prevent systems from power surges and storms.

- Where? Throughout the panel.

Circuit breakers keep a connection from short-circuiting or overloading. The various styles all keep operations calm from an amperage standpoint.

Circuit breakers keep a connection from short-circuiting or overloading. The various styles all keep operations calm from an amperage standpoint.

- Main breakers handle 120V–480V in most industrial applications. A common landing spot for these in panel designs is the top of the enclosure, since that’s where power typically enters the panel.

- Branch breakers prevent short-circuiting (and, in some uses, overload) for each load, such as heaters and motors.

- Supplementary breakers provide extra protection for high-priority control components and devices.

An industrial PLC panel may include other parts with similar (but less comprehensive) functions.

Surge suppressors are in place to protect against short-circuiting due to voltage (rather than amperage). This is the component that’ll stop or reduce havoc downstream in the panel if a lightning strike or power surge occurs (but it won’t prevent overload).

Fuses stop an electric circuit from overloading in times of high current. These have a one-time function, once they activate, they become an open circuit and require replacement. They don’t protect against short-circuiting.

Power Supply

What? Changes alternating current (AC) voltage to direct current (DC) power.

Why? Lowers voltage for a safe, more controlled current.

Where? Passed along to any devices (i.e. interfaces and PLCs) that need DC voltage.

Like the name says, the power supply is a source of electricity for your panel. Most power supplies convert 480V or 120V AC power into 24V DC, a commonly shared current level required in panel components.

The power supply can also act like a regulator for the voltage each part receives. For example, it can control the flow to a motor to reduce overload concerns (except in extreme cases your breakers and fuses should address).

Power Distribution

What? A block usually made of machined aluminum. Features include connecting holes in the top for larger wires, and connecting holes below for smaller wires.

Why? Splits a large wire’s power into smaller wires for safe, efficient voltage distribution.

Where? Brings energy to the components that require either AC or DC voltage.

An industrial control panel includes two power distribution components: AC and DC. Both forms of current are useful in several areas of the electrical panel. In the DC block’s case, it takes the voltage recently converted from AC by the power supply and distributes it to DC-needy components.

Communications

What? Networking equipment.

Why? Allows the PLC and any compatible devices to “talk” to each other.

Where? Any place where communication is key!

All modern control panels include a central communications hub so the PLC can direct other devices on the production line. In layman’s terms, the device sends signals to the other parts so they can do their jobs and keep production running smoothly.

To communicate, industrial control boxes include one of two options.

- Ethernet switches allow for network communications between the PLC, HMI, SCADA systems, and other smart components. They tend to use Category 5 or 6 cable.

- Radios (the industrial kind) include an antenna for communication and a polyphaser to stop damage from lighting strikes. You’ll only find a radio in modern panels when local communication via ethernet is impossible.

Motor Drives

What? An electromechanical system that includes a motor.

Why? Drives a device, usually one capable of monitoring data and outputs.

Where? Motors and other areas that need oversight of input/output. Designed to survive in factory environments (vibration, noise).

You could call these components the brain and nervous system of an electric control panel. They all control motors in some way, although not all drives are equally critical to the assembly.

The programmable logic controller deals in data, sending to and receiving from all connected equipment and processes. The PLC analyzes that data and translates it into information engineers can use to evaluate the operation.

PLCs keep tabs on the state of sensor inputs to control outputs, including:

- Motors

- HMIs

- Solenoids

- Valves

- Lights

The variable frequency drive (VFD) primarily controls motor speed, though it can monitor other motor data too. A VFD’s ability to adjust speed based on specific job requirements is a huge energy saver.

Soft starters offer an alternative method of AC motor power-up. This type of controller slowly ramps the motor up to full speed, reducing strain and prolonging service life.

Terminal Block

What? A modular, insulated block that connects and splices two or more wires.

Why? Organizes wires coming from various sources and directs them to the appropriate electrical devices.

Where? The connection point where external equipment is wired into the panel.

A terminal block is an entry point for electricity to flow from incoming wires to different parts of the control panel. It also serves as a junction with other internal components, like switches and relays.

Above all else, a control panel’s terminal block allows for safe, reliable connection of multiple wires.

Blocks are available in many sizes and setups, depending on the control panel’s function.

Relays & Contactors

What? Electrically operated on/off switches that control mechanized functions.

Why? Make or break energy supply to a device based on PLC commands.

Where? Any electrical devices in the panel.

Relays and contactors have similar roles, but on different scales.

Relays are smaller switches that open and close circuits when they get electrical signals from an external source. A key part of industrial automation systems, they control low-current-switching functions like:

- Fans

- Lights

- Pumps

You can combine relays for more complex control features, such as switching power sources or reversing a motor’s direction.

Contactors (aka motor starters) control large voltage loads for high-current-rating devices. These larger relays handle advanced functions like:

- Precise motor control

- Industrial drives

- Processing heating systems

Contactors start motors at full speed and voltage. Because it includes an overload relay as well, the contractor can control the situation during both startup and operation of the motor.

HMI

What? Human-machine interface with data output and human input features.

Why? Human operation and oversight of the associated machine or process. A way to see and interact with information the PLC compiles.

Where? Often mounted to the panel’s door.

The human-machine interface is all about making sure those responsible for an operation’s success can evaluate and adjust settings quickly and easily. An HMI includes all or some of these:

- Buttons

- Switches

- Screens

- Dials

- Keyboards

- Joysticks

To help you stay on top of a line’s status and performance, an HMI may be tied to production trends, commands, performance indicators, and more.

Transformer

What? A passive device with primary and secondary coil windings for transferring electrical energy.

Why? Reduce or increase AC voltages between circuits for power transfer that doesn’t change the current’s frequency.

Where? Common control devices, such as PLCs and HMIs.

This component sends energy to devices that are connected to the control panel, but can’t directly connect to the power supply.

Since the current could hurt many components on its own, an industrial control panel transformer converts the incoming voltage for safe use. One common application for a transformer is reducing 480V AC to 120V AC.

Wire Duct & DIN Rail

What? Wire duct: Rigid tray that holds wires. DIN rail: Thin strip of metal that holds mounted components

Why? Organizes and maximizes space for wires, breakers, boards, and other components.

Where? Wire duct: Pretty much anywhere cable management is useful. DIN: attached to the inside of the enclosure or directly to an external wall.

While they address different components of the panel, wire ducts and DIN rails address the same issue: space management. They organize and stabilize other design elements so they fit the enclosure and run smoothly and safely.

Wire ducts act as raceways that protect your industrial PLC from damage and performance dips. Perhaps even more importantly, they help you avoid a tangled mess when you need to access the box for maintenance or modifications.

There are several types of wire ducts available to meet certain design goals:

- Narrow slot – for small-diameter wires

- Wide slot – for thicker wires

- Unslotted (aka solid wall) – for extra protection, at the cost of higher difficulty of access

- Round hole – support wires at varying positions & heights, keeping walls rigid

A DIN rail mechanically supports small electrical components. Items commonly mounted on a DIN include:

- PLCs

- Circuit breakers

- Terminal blocks

- Relays

- Motor controllers

These components need support, but their design often doesn’t allow for direct mounting to an enclosure wall. In these cases, the DIN steps in to ensure proper function and organization of the components.

Enclosure, Backplate, & Grounding Panels

Enclosure, Backplate, & Grounding Panels

What? Structural components that form the skin and skeleton of an electrical control system.

Why? To support the panel, both physically and in terms of its safety.

Where? They’re the housing and outer components of a panel.

The enclosure ensures the well-being of not just the panel, but also its operator. The end use will determine the type of enclosure design on a panel:

- Open – components face environmental exposure

- Enclosed – protects components from the environment, often by using metal materials and a locking door(s)

The finer details of a PLC casing’s design depend on its potential exposure to moisture, dust, and explosions.

The backplate, or back panel, supports rails and ducts from its mounted position just inside the enclosure. This structural sheet also allows the manufacturer to fabricate and assemble the control panel separately from its enclosure.

The grounding panel protects the device from electric noise and workers from electric shocks. This panel resides deep underground to ensure no human (or animal) touches it.

Custom Electrical Control Panels – a Component of Your Line?

The control panel is critical to your facility’s success. That means the electronic components you source are critical, too.

When motor controllers, relays, or switches fail, production slows or stops in a flash. Every hour missed due to maintenance or replacement equals lost revenue.

Because every production line has its own needs to help meet its goals, this list doesn’t cover every component out there, nor the nuances of customized use. Your line may need a custom control panel engineered to demanding specs and unique end uses.

Now that you’ve nailed down the basics, seize the day with more tips on electrical components and sourcing:

Share this

- Components (39)

- Cost (29)

- Distribution (21)

- Materials (21)

- Cables & Wires (20)

- Supply Chain (19)

- Standards & Certifications (18)

- UL (17)

- Control Panels (16)

- Safety (14)

- Design (13)

- Contract Manufacturing (11)

- Inventory Management (11)

- News (10)

- Jacketing & Insulation (9)

- Suppliers (8)

- Wiring (8)

- Availability (7)

- Design & Engineering (7)

- Obsolescence Management (7)

- Testing & Prototyping (7)

- Maintenance & Downtime (6)

- Temperature & Fire Resistance (6)

- Enclosures (5)

- Manufacturing (5)

- Circuit Protection (4)

- Data Centers (4)

- Kitting & Fulfillment (4)

- Labeling (4)

- Sensors (4)

- Corrosion (3)

- Datacom (3)

- Cooling & Fans (2)

- Supplier Spotlight (2)

- Automation (1)

- Honeywell (1)

- PLCs (1)

- Relays (1)

- Security (1)

- November 2025 (1)

- October 2025 (1)

- August 2025 (1)

- July 2025 (6)

- June 2025 (4)

- May 2025 (4)

- April 2025 (3)

- March 2025 (11)

- February 2025 (3)

- January 2025 (2)

- December 2024 (1)

- November 2024 (1)

- October 2024 (1)

- September 2024 (3)

- August 2024 (1)

- July 2024 (4)

- June 2024 (3)

- April 2024 (2)

- March 2024 (1)

- January 2024 (1)

- October 2023 (1)

- June 2023 (1)

- May 2023 (1)

- April 2023 (1)

- March 2023 (2)

- October 2022 (1)

- March 2021 (3)

Comments (3)