Share this

New Networking Equipment Your Datacom Team Should Get to Know

by Joe O'Donnell on Mar 18, 2025 6:19:05 PM

Advances in data communication move as quickly as the transmissions themselves. It can be tough for an electronics sourcing team to keep up.

Advances in data communication move as quickly as the transmissions themselves. It can be tough for an electronics sourcing team to keep up.

Ever wonder what improvements you’re missing out on?

Staying ahead of technical requirements – and your competitors – means keeping up with new networking equipment that could transform your setup’s efficiency. It’s a whirlwind out there, so we’ve curated some noteworthy datacom products that are not only meeting stricter standards, but also setting new standards themselves.

5 Exciting Developments in New Networking Equipment

From the ultra-responsive to the high-capacity, these are today’s (and tomorrow’s) need-to-know product categories:

- AI surveillance

- Advanced data center PDUs

- OM5 high-density cables

- Installation-friendly solar power parts

- Components for the next “supercomputers” – cars

These emerging trends in data communication aren’t cute, trivial, or passing fads. In the right project – maybe yours – they could be infrastructure-savers.

AI-Based Surveillance

AI-Based Surveillance

With all this connectivity, an easy-to-use, end-to-end security setup means more than ever.

Like everything else today, there’s an AI for that.

A few security product manufacturers have started differentiating themselves by building sophisticated AI into their lineups. The technology recognizes faces and picks up on certain actions, giving new meaning to the term “hands-off solution.”

For example, IDIS markets new cameras and recorders as being powered by its branded Deep Learning Engine, which it says can reach 98% accuracy. IDIS’ Edge AI camera line boosts crisis response time and operational efficiency by offering:

- Detection and classification of intruders, loiterers, autos, & bikes

- Up to 600 images per second, tops in the industry

- Ability to upgrade legacy hardware & cameras at no additional processing power

Learn more about IDIS surveillance solutions here.

Power Distribution Units (PDUs)

Power Distribution Units (PDUs)

In data center racks alone, the market for power distribution units will hit an estimated $2.8 billion in 2025 and balloon to $4.1 billion by 2030.

What’s the fuss that’s made PDUs one of the hottest datacom equipment power trends?

In data processing facilities, the increased strain from generative AI platforms has prompted (no pun intended) the need for stronger power sources. In fact, output has increased just about everywhere. To veteran IT engineers, it seems like only yesterday we were talking about 16-amp and 30-amp units – now we’re talking 100-amp monstrosities.

That’s why power distribution units have essentially become power strips on steroids. Mounted on racks in data centers and cloud setups, these centralized power sources come with multiple outlets that can manage power efficiently system-wide.

Whatever capabilities you want (smart, sensing, etc.), PDUs can probably handle it these days. Advanced PDUs come with features like power metering and remote monitoring, which can help data farms reduce the cost of operating.

A couple of recent examples include:

- APC NetShelter Rack PDU – APC switched-rack units provide advanced load and sequencing control, along with real-time remote management. The latest release can handle up to 5 kW of power and a current capacity of 30 amps. It’s an impressive heavy-duty option for colocation, large data centers, and other distributed IT sites.

-

nVent Hoffman Intelligent PDU – The RackPower line of units is a secure remote-monitoring solution for cabinets, open-frame racks, and wall-mount enclosures. The units are available in horizontal 19 in. racks or vertical mounts, along with a host of other custom configuration options.

OM5 Fiber-Optic Cable – High-Density

A growing population means more mobile devices, more streaming … more everything, really. Out of necessity, this has led to major advances in network switching infrastructure over the past decade. In the past 1-2 years alone, AI platforms have skyrocketed that demand – and strain – to new heights.

Thus, America needs faster, more reliable, and higher-density data center networking equipment.

By now, you’re probably familiar with fiber-optics as one of the types of electrical cables critical to the future of U.S. infrastructure. We’ve been living in the world of level 3 and 4 OM (optical multimode) installations for a while now, but that’s swiftly changing.

|

Cable |

Year Introduced |

Uses Today |

|

OM1 |

1989 |

Legacy installations (buildings, small campuses) |

|

OM2 |

1998 |

Medium-speed applications (buildings, small campuses) |

|

OM3 |

2003 |

High data transfer over medium distances (data centers, big campuses) |

|

OM4 |

2009 |

High-speed networks (data centers, large enterprise setups) |

|

OM5 |

2016* |

High speed and bandwidth (data centers, automated monitoring, manufacturing) |

Why the asterisk next to OM5? Despite being around for nearly a decade, it’s rare to spot a live OM5 in the field. That is, until the recent explosion of AI.

As server rooms sag under the weight of increased processing from ChatGPT and other AI platforms, more datacom engineers are turning to OM5 fiber-optic cables. OM5 is a lifeline for data centers that require:

- High bandwidth

- High speed

- A futureproof solution

OM5 works over medium distances as a cost-effective way to support current technologies, like 40/100G Ethernet, and future upgrades. Here are the key specs you’ll want to grasp:

- Allows for simultaneous signals to move across the same fiber, increasing capacity and throughput without extra cabling

- Bandwidth up to 100 Gbps, with potential to support future applications up to 400 Gbps

- Supports 40G and 100G Ethernet up to 440m and 150m, respectively

- Backward-compatible with OM3 and OM4 systems

It’s not just enough for new datacom cables to be powerful. Technicians maintaining data centers and 5G networks also crave higher-density fiber solutions. The latest high-density fiber-optic cables are raising the bar for capacity and performance in small spaces. This allows engineers to increase the number of cords in a cabinet.

One of the biggest influences changing datacom cable design today is the product’s connector type. Just as control panels are getting smaller, so are connectors. The smaller they are, the more the installer can fit into a PAL.

Solar Power Components Galore

Solar energy is no longer a new concept – it’s been commercially available since the 1950s. That hasn’t stopped manufacturers from refining even the smallest parts of these assemblies.

Much like 70 years ago, the top factors in solar component engineering are:

- Installation costs

- Safety

- Airflow

Here are a few new solar components helping OEM buyers do just that:

Heyco’s Installation Helpers

Heyco solar products specialize in diversity that doesn’t sacrifice reliability. The line’s wide range of materials and applications (from residential to utility-scale) all come with a sweeping, 20-year warranty.

Recent releases you should get to know include:

- Helios Edge PV Module Clip – These clever products support 1-2 cables for panel frames ranging from 1-3mm. All installation takes is a little fingertip pressure – from there, the stainless steel teeth underneath the nylon overmold will provide a reliable hold. The Edge Clip features UL 3741-compliant plastic wire management to insulate cables from aluminum solar panel frames.

Tear-Away Liquid Tight Cordgrips – These function as a plug prior to cable assembly, protecting your enclosure from rain, insects, and pollutants. When it’s time for network installation, puncture the fitting’s edge with a screwdriver and tear away the inner section for easy cable pass-through.

Tear-Away Liquid Tight Cordgrips – These function as a plug prior to cable assembly, protecting your enclosure from rain, insects, and pollutants. When it’s time for network installation, puncture the fitting’s edge with a screwdriver and tear away the inner section for easy cable pass-through.

Learn more about Heyco component supplies here.

Panduit’s Sprawling Solutions

Panduit’s website harps on its ability to streamline your “balance of system,” which is a fancy way of saying its expansive solar product line can cover up to 75% of your installation.

There are indeed almost too many products to count, so let’s focus on a few of Panduit’s latest:

- Nylon 612 Cable Ties – These fasteners are ideal for cable management on galvanized surfaces and frames in harsh external setups. Their high-strength material is resistant to UV, chemical corrosion, acid rain, and temperatures ranging from -76 to 194°F.

- MEC125 Stainless Steel Solar Edge Clip – These tough-yet-attractive fasteners are for routing cables underneath panels in coastal, humid, and high-precipitation solar park areas. The MEC125 can accommodate four wires (0.200-0.295" diameter each) – simply push it onto the module and clip the wires under the spring tab.

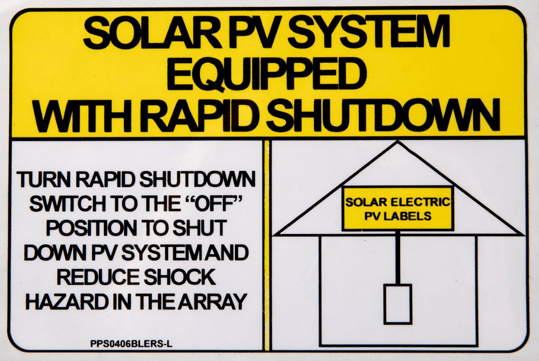

- Preprinted labels – A faded warning sign does nobody any favors, so Panduit manufactures labels that last 7-10 years under intense UV rays. The hyper-durable design complies with NEC2020 and UL standards, and is easy to peel and stick on surfaces anywhere.

See more Panduit solutions here.

Snake Tray’s Bendable Cable Management

In the name of easy installation, the Solar Snake Tray markets itself as the only weatherproof, hand-bendable conduit for DC solar panel circuitry. Despite being utility- and industrial-grade, this product series is cost-effective in the right application.

Its main selling points are:

- Patented “lobster trap” design keeps away rain, snow, and hurricane-force winds

- NEC-compliant and free of risky wire ties

- Built-in rings for a variety of mounting styles

- Trays join via a single connector for a 15-second bonded attachment tray to tray

See Snake Tray’s cable management solutions here.

Components for Cars – The Next Supercomputers

Are you driving a computer to work?

More or less, yes. With today’s vehicles featuring everything from steering correction to biometric security, the auto industry is basically building giant CPUs on wheels. The number of electronic components in vehicles – even traditional combustion-engine models – has exploded in the past 3 decades.

|

|

Cars in 2000 |

Cars Today |

|

# of Motors |

20 to 30 |

30 to 100+ |

|

# of Sensors |

20 to 40 |

100 to 200 |

Charging stations have also become quite complex (or already were) to meet the needs of electric vehicle drivers and those who oversee the stations. Chargers need to not only power the vehicle efficiently, but also be capable of payment processing and remote communication.

Here are some of our favorite new component solutions:

Here are some of our favorite new component solutions:

- Battery Safety Electrolyte Sensor – Honeywell hopes to make lithium-ion batteries safer with its new EV sensor. This component can detect gases released early from a failing battery cell, which can serve as precursors to thermal runaway and battery fires. Capable of issuing warnings 5-20 minutes before a fire, the sensor allows operators to take action while helping auto manufacturers meet critical safety regulations.

- SurLok Plus series expansion – Amphenol’s popular connector line now includes more sizes and configurations to meet needs in energy storage, high-power connection, and transfer. These compression lug-style connectors are IP67-rated for high reliability and are touch-safe. The series’ industry-standard termination options eliminate the need for special torque tools.

- ER Series AC charging cable and inlet – Also an Amphenol creation, this product meets SAE J1772 standards for overnight and rapid AC charging in personal and commercial vehicles (up to 250V). Its flexibility in charging mode extends to both portable and fixed installations, The sturdy build includes IP67 and Type 3S ratings for exceptional durability against dust, water, ice, and temperatures from -22° to 122°F.

Learn more about Amphenol’s product line here.

Learn More re: New & Upcoming Networking Products

From ultra-responsive smart PDUs to high-capacity fiber optics, today’s innovations can empower your networking systems of tomorrow. Whether you’re upgrading an enterprise network or optimizing a data center, the communications products above might be your key to a future that’s, well … futureproof.

There’s so much more commercial and industrial networking equipment that’s either just hit shelves or is coming down the pipeline. To get a fuller view of what’s available today, see our networking equipment supplier page:

Share this

- Components (36)

- Cost (28)

- Distribution (20)

- Materials (19)

- Standards & Certifications (18)

- Supply Chain (17)

- UL (17)

- Control Panels (16)

- Cables & Wires (15)

- Safety (14)

- Design (12)

- Contract Manufacturing (10)

- Inventory Management (10)

- Jacketing & Insulation (9)

- News (9)

- Availability (7)

- Design & Engineering (7)

- Obsolescence Management (7)

- Testing & Prototyping (7)

- Maintenance & Downtime (6)

- Temperature & Fire Resistance (6)

- Wiring (6)

- Enclosures (5)

- Suppliers (5)

- Kitting & Fulfillment (4)

- Manufacturing (4)

- Circuit Protection (3)

- Corrosion (3)

- Labeling (3)

- Sensors (3)

- Cooling & Fans (2)

- Data Centers (2)

- Datacom (2)

- Automation (1)

- PLCs (1)

- Relays (1)

- Security (1)

- March 2025 (10)

- February 2025 (3)

- January 2025 (2)

- December 2024 (1)

- November 2024 (1)

- October 2024 (1)

- September 2024 (4)

- August 2024 (1)

- July 2024 (4)

- June 2024 (3)

- April 2024 (3)

- March 2024 (1)

- January 2024 (2)

- December 2023 (1)

- October 2023 (2)

- July 2023 (1)

- June 2023 (1)

- May 2023 (4)

- April 2023 (2)

- March 2023 (3)

- October 2022 (1)

- March 2021 (3)

No Comments Yet

Let us know what you think