Share this

The Anatomy of a Cable: Inside Industrial Electrical Wiring

by Simcona on May 30, 2025 1:34:44 PM

Without sturdy cabling, even the most heavy-duty, industrial-grade equipment can go quiet.

Cables and wires aren’t the sexiest part of a design, but they’re some of the hardest-working. The anatomy of a cable gives you a clearer look at how each part contributes to overall performance — a helpful reference when choosing the right solution for your application.

Every component has a job, and the materials or formats you pick will shape how the cable handles real-world conditions. With so many options available, it’s worth breaking things down:

(We won’t discuss fiber-optic cables much today because they use specialized materials.)

Understanding the 5-Part Anatomy of a Cable

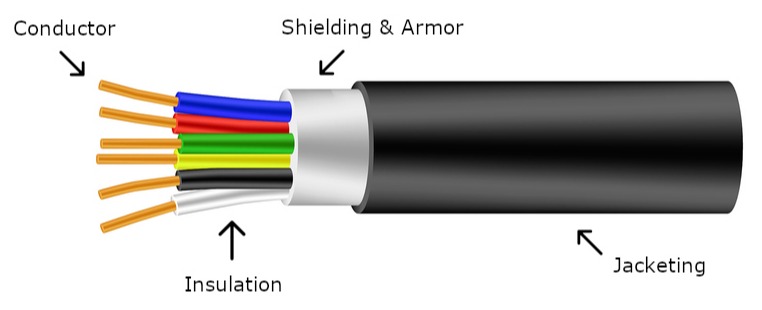

An industrial electric cable consists of multiple wires encased in a single covering.

You can break that definition down further to identify five parts of a cable:

- Conductors

- Insulation

- Shielding & armor

- Jacketing

- Connectors

Conductors

A cable’s conductor is the core that transports electrical current in one or more directions of flow. In other words, it’s that shiny, bare wire.

Cable conductor size is one major element of a cable’s design. U.S. and international standards like IEC 60228 specify sizes for cross-sections (0.5 mm2 to 2,500 mm2) for conductors in a range of electrical cable types. Requirements for numbers and resistance values of wires are also part of IEC’s standard.

Conductor material is lean on options because the ability to pass on electrical current is critical to functionality.

- Copper – versatile and highly conductive

- Aluminum – lightweight and affordable, but less conductive

- Steel – poor conductivity, useful for grounding, excellent mechanical strength

Copper conductors can be either solid or stranded, with the latter providing more durability and flexibility. Stranded copper cables in automated assembly plants can withstand millions of flex cycles before failing. In industrial settings, copper is the clear-cut best conductor for cables.

Another reason copper tops the list is that it’s compatible with a variety of plating options. The cable manufacturer can coat the surface of each wire strand to add solderability, corrosion resistance, and electrical properties at high frequencies.

For copper conductors, three common coatings are:

- Tin – cheap, easy to find

- Silver & nickel – durable in extreme temperatures

- Lead (largely phased out due to health hazards)

Insulation

A cable's insulation has a huge impact on service life and effectiveness.

Cable insulation separates each conductor inside, both electrically and physically. It’s a nonconductive middleman, keeping the peace by preventing damage from:

- Current leakage into nearby wires & cables

- Moisture

- Heat

The insulation determines many of the electrical properties of a cable. For example, its thickness determines voltage rating. Insulation that can work at higher operating temperatures can carry more current without failing.

Electrical cable insulation materials are aplenty. Many, but not all, are either thermoset (rubber) or thermoplastic.

|

Material |

Subcategories |

Traits |

|

Plastic |

PVC varieties, polyethylene varieties, polypropylene, polyurethane, nylon |

High electrical resistance, ductility, UV resistance, & fire resistance; low cost |

|

Rubber |

Thermoplastic rubber, neoprene, SBR, silicone, fiberglass, EPR, CSPE, EPDM |

More flexible, especially at low temperatures; higher cost; better overload endurance |

|

Fluoropolymer |

PFA, PTFE, FEP, ETFE, ECTFE, PVDF |

Highly resistant to acid, solvents, & bases |

Shielding & Armoring

Much like connectors, electrical metal cable protection comes in both mechanical and electrical forms.

Cable shielding is a material that’s electrically conductive and surrounds a wire or cable. It contains electrical energy so the cable’s signal doesn’t radiate and interfere with nearby cables and circuitry. Likewise, it protects the cable’s own signal from disruption by outside interference.

Popular types of electrical cable shields include:

- Foil – 100% coverage, low cost, thin and lightweight, easy to terminate, can be color coded, effective at high frequencies

- Braid – 40-98% coverage, stronger than foil, better against low-frequency interference, good flex life

- Spiral – Up to 97% coverage, superior flexibility, great for coil cords

Cable armoring protects the mechanical side of the operation. It’s able to withstand crushing and impact forces through use of strong metals. For example, popular cable manufacturer Belden offers these armor types:

|

Type |

Mechanical |

Direct Burial? |

Moisture/ |

Flexibility |

MC Rating* |

MC-HL Rating** |

|

Steel |

Best |

Yes |

Not recommended |

Best |

Yes |

No (Cl1 D2) |

|

Aluminum |

Better |

Yes |

Not recommended |

Best |

Yes |

No (Cl1 D2) |

|

Metal Tapes |

Good |

Yes |

Good |

Better – corrugated |

No |

No |

*MC Rating = “metal clad,” referring to metallic sheathing in accordance with UL 1569 cable standards

**MC-HL Rating = metal-clad cable for hazardous locations, in accordance with UL 2225 cable and fitting standards

Jacketing

An industrial cable’s jacket does pretty much what you’d guess based on the name. This cable component is an outer covering that goes around a group of conductors or other core components.

Like your warmest winter coat, a cable jacket’s job is to protect. The jacket is the first line of defense against fire, the rigors of installation, and other hazards. Also like your winter coat (hopefully), cable jacketing improves aesthetics.

Most electrical cable jacketing is thermoplastic, as this material group can repeatedly become soft and formable when hot.

Many of the materials best practices from insulation apply to jacketing as well. Here are a few extra application-specific notes:

- PVC – Flame-resistant; must be combined with other ingredients so it’s not too rigid and prone to failure at processing temperatures

- Polyethylene – Good for wet locations and direct burial; not flexible at low temps; available in many density options

- Chlorinated polyethylene – Tough; chemical-resistant; flame-retardant; doesn’t outgas byproducts that can damage switches

- Thermoplastic elastomer & rubber – Great flexibility in temperatures down to -60 °C; highly resistant to solvents and water; low corrosive outgassing, acid, & alkali resistance

- Polyurethane – 2x strength and 3x abrasion resistance of PVC; temp rating of -20 °C to 90 °C

- Thermosets (SBR, CSPE, CPE) – Non-plastic and can’t be reshaped with heat; useful in harsh environments like utility, power, mining, and hard service cords

Connectors

An electric cable acts as transportation for power or signal between parts of an assembly. Think of cables and wires as roads, and cable connectors as bridges and intersections.

Connections can be both mechanical and electrical:

- Connectors – Electrical entry device with a plastic or ceramic outside and copper alloy terminal pins

- Cord grips – Mechanical entry device made of steel, brass, or aluminum

On the electric side, types of cable connectors include:

- Twisted-pair – insulation displacement and connecting to patch panels, wall-plates, and punch-down blocks

- Coaxial – prevent interference in cables that carry high frequency, multi-megahertz signals

- Fiber-optic – align fibers so light can pass, allowing for quicker connection/disconnection than splicing

Cord grips (also called cable connectors, fittings, strain reliefs, or glands) provide protection and termination in instrumentation, automation, and communications settings. Applications prone to moisture contact or pressure use cord grips with synthetic rubber or other elastomer seals. Certain types of fittings also prevent flammable gas from entering equipment enclosures.

Using What You Know About the Anatomy of a Cable

By now, you’ve probably got a better feel for how much industrial cables and wiring matter to a system’s success. They may not be the flashiest components (unless they’ve got an extra-snazzy jacket), but choosing the right ones is a big deal when it comes to meeting your specs.

Of course, the anatomy of a cable can get even more nuanced than what we’ve covered here. If you’re working with unique requirements, a custom cable manufacturer or distributor can help align the design with your application.

Free Resource: A Deep Dive Into Components That Matter

Grab our free guide to help you source and specify all components with confidence.

Share this

- Components (37)

- Cost (28)

- Distribution (20)

- Materials (19)

- Standards & Certifications (18)

- Supply Chain (17)

- UL (17)

- Cables & Wires (16)

- Control Panels (16)

- Safety (14)

- Design (12)

- Contract Manufacturing (11)

- Inventory Management (10)

- Jacketing & Insulation (9)

- News (9)

- Availability (7)

- Design & Engineering (7)

- Obsolescence Management (7)

- Testing & Prototyping (7)

- Maintenance & Downtime (6)

- Suppliers (6)

- Temperature & Fire Resistance (6)

- Wiring (6)

- Enclosures (5)

- Circuit Protection (4)

- Data Centers (4)

- Kitting & Fulfillment (4)

- Manufacturing (4)

- Sensors (4)

- Corrosion (3)

- Labeling (3)

- Cooling & Fans (2)

- Datacom (2)

- Automation (1)

- Honeywell (1)

- PLCs (1)

- Relays (1)

- Security (1)

- Supplier Spotlight (1)

- May 2025 (4)

- April 2025 (3)

- March 2025 (12)

- February 2025 (3)

- January 2025 (2)

- December 2024 (1)

- November 2024 (1)

- October 2024 (1)

- September 2024 (3)

- August 2024 (1)

- July 2024 (4)

- June 2024 (3)

- April 2024 (3)

- March 2024 (1)

- January 2024 (1)

- October 2023 (2)

- July 2023 (1)

- June 2023 (1)

- May 2023 (2)

- April 2023 (2)

- March 2023 (2)

- October 2022 (1)

- March 2021 (3)

Comments (3)