Share this

Panel Shops vs. Contract Panel Manufacturers

by Dawn Bertman on Jan 23, 2024 12:12:33 PM

The charm of a flawed-yet-well-intentioned mom-and-pop shop? Or the might of a turnkey supplier?

The charm of a flawed-yet-well-intentioned mom-and-pop shop? Or the might of a turnkey supplier?

An obedient order-taker? Or an equal problem-solver?

If you’re here, you probably already know that outsourcing to a control panel supplier is a smart move for many projects. Going the third-party route for this highly manual process allows OEMs to focus on their core competencies, along with marketing and R&D.

So, where to go?

This probably isn’t the first time you’ve waffled between investing in a smaller business vs. one with broader resources. Or perhaps this is the first time you’ve heard that there’s a difference between a “shop” and a “true contractor.” It’s not like panel building companies slap this distinction on their front window.

Know this: There can be several huge differences. While they’re not always explicit, there are plenty of fairly obvious signs that’ll indicate which outsourcing option is best for you.

(Related Post: How In-House vs. Contract Panel Building Influences Design)

If You Go to a Control Panel Shop …

In the context we’re discussing today, an electrical panel shop is a smaller, mom-and-pop-style operation. It may do business on a more local scale, offering general production and assembly of electrical control panels.

This more intimate setting plays right into both the strengths and weaknesses of panel shops:

Pros

➕ Accepts small jobs

➕ Cost-competitive at low volumes

➕ Personal attention

A smaller-scale panel shop typically caters to one-off and low-volume production runs. Not only is it more likely to accept such a request, it also may turn it around more quickly. To many panel shops, no job is too small – including rewiring services and schematic creation on existing panels.

If you’re looking to validate a design with a prototype, a small shop can get you up and running.

With less overhead, panel shops may be able to churn out a lower initial quote. If you’re strictly price shopping and don’t have demanding quality or regulatory requirements, you might have better luck with a job shop.

You may also consider the less-formal relationship a better fit in terms of receiving personalized attention. With few layers of management and bureaucracy, a smaller panel supplier can communicate and make decisions at a consistent pace (assuming it’s a well-run operation).

Such a relationship may put you in closer contact with the owner or key engineers. Direct communication with the people actually working on your project can reduce misunderstandings and lead to a product that closely matches your specifications.

Cons

➖ Higher material & part costs

➖ Lack of big-picture insight

➖ No quality standards

➖ Can’t scale production

➖ Lower level of service

The limits of mom-and-pop control panel services show up as you start to ask more of the supplier:

- Material & part costs: As a small-scale specialist, a panel shop doesn’t buy supplies in large enough quantities to negotiate the lowest prices. Because mass production isn’t in its nature, a shop could charge higher per-unit prices.

- Big-picture insight: A local panel supplier is often a makeshift operation with electricians slapping stuff together based on your instructions. The engineers aren’t necessarily building with the final product in mind. Either way, they may not possess the skills or discretion to recommend improvements to the control panel’s design.

- Quality standards: Inspection technology, industry certifications, and other facets of QA are prohibitively pricey for some companies. For example, becoming a UL 508A-certified panel shop can cost a company tens of thousands of dollars, plus annual fees. Without these certifications, there's no formal assurance of the panels meeting certain safety and quality standards.

- Scaling production: If your project gets big enough, you’ll eventually have to further outsource, adding a vendor to fit your volume needs. Be careful about your growth trajectory outpacing your supplier’s capabilities, as this could create downtime.

- Level of service: With limited capacity and resources, a panel shop’s service level might be lower, especially if you’re buying a small number. You might find yourself getting less attention than larger, more profitable clients. This can result in lackluster lead times and post-sale support experiences.

If You Go to a Contract Panel Manufacturer

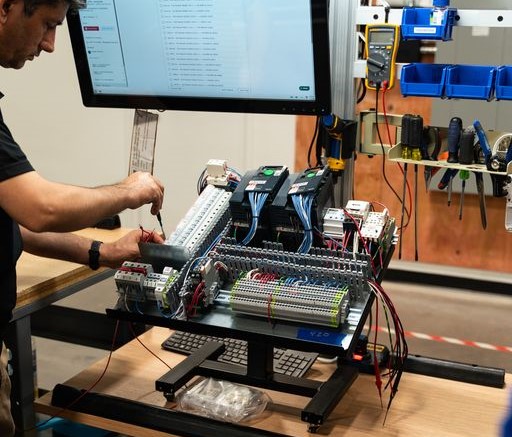

A full-service control panel manufacturer partners with OEMs on a more influential level, possibly assisting with design, engineering, production, and inventory management. Industrial panel contractors tend to work on more complex and high-risk applications.

Pros

➕ Broader volumes

➕ Stronger quality control

➕ Higher engineering competency

➕ Breadth of services

➕ Cost-efficient operation

The value of contract panel services picks up as your needs start to outgrow what a job shop can handle:

The value of contract panel services picks up as your needs start to outgrow what a job shop can handle:

- Volumes: With more people, stations, and technology dedicated to the cause, a larger contractor can take on a much broader range of orders. If demand suddenly increases or you want to expand your market reach, a contract manufacturer is better-suited to ramp up velocity. Ordering at higher volumes makes for a better freight rate, too. (Don’t underestimate how big and heavy these panels are!)

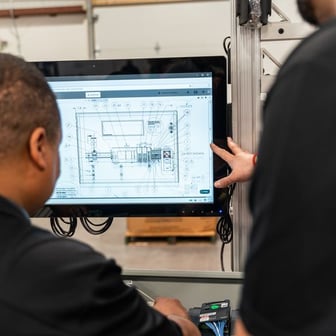

- Quality control: A larger manufacturer has to adhere to more standards and regulations because it often serves clients in critical industries (medical, aerospace, etc.). That means it’ll have rigorous quality control processes and certifications – like UL 508A and ISO – in place. It’ll also have more investment dollars dedicated to the latest QA technology and the greatest panel engineers.

- Engineering competency: A turnkey contractor is more likely to accept requests for complex or highly custom control panel designs – and excel at them. Its team likely owns experience in design and engineering for high-reliability applications. A true contractor does more than take orders – it also riffs on your original concept for better manufacturability and reliability.

- Breadth of services: Turnkey control panel building services can mitigate risk on your end by leading the way on supply chain management. This includes material sourcing, warehousing, and component availability forecasting. A manufacturer with a broad supplier network and purchasing power is better equipped to handle component shortages and other market changes.

- Cost-efficient: A contract manufacturer enjoys economy of scale, meaning it can bulk-buy materials and parts at a lower cost than smaller shops. It can also identify the most efficient way to manufacture the panel, plus any opportunities for streamlining its layout or using a lower-cost alternative component. As your order volume or complexity grows, so does the need for this process efficiency.

Cons

➖ Allergic to small orders

➖ May communicate less

The biggest roadblock to working with a more robust supplier is order size. A contract manufacturer generally isn’t interested in one-off projects, unless there will be production volume to follow (as in, 30-100 per month).

There are two types of customers that work with an industrial control panel manufacturer. One type makes repeat panel orders for continuous builds. The other type orders a single, $30,000 panel, but with plans for future adjustments and versions.

If your request is for 10-20 panels annually, at a price of less than $1,000 per panel, you might get a “Thanks, but no thanks” from the vendor.

Another complaint you may hear about the contract manufacturing experience is the nature of communication during the relationship. Larger contractors may have a longer chain of command (perhaps more like a messy spiderweb), leading to slower decision-making and communication. Usually, this is simply because a more professional, higher-stakes operation comes with more complex and formal processes.

Of course, your experience will vary by supplier. Vet your potential vendor for reliability, and there should be no problem.

Don’t (Panel) Shop ‘til You Drop

“Panel shop” is a blanket term many use to describe anyone who builds control panels. In reality, there are huge differences in service between a smaller panel shop and a full-fledged contract manufacturer.

A panel shop is an order-taker that’s sufficient for small, low-impact projects. A panel contractor is a problem-solver that opens innovative avenues to quality and cost reduction.

To get the level of service your project actually needs, weigh its requirements against the typical strengths and weaknesses of panel shops and contract manufacturers. If you’re facing strict quality standards or a complex or unique design, opt for a contractor with industrial-grade experience.

To learn more about your options with a UL508a panel shop contractor, as your pressing engineering questions here:

Share this

- Components (39)

- Cost (29)

- Distribution (21)

- Materials (21)

- Cables & Wires (20)

- Supply Chain (19)

- Standards & Certifications (18)

- UL (17)

- Control Panels (16)

- Safety (14)

- Design (13)

- Contract Manufacturing (11)

- Inventory Management (11)

- News (10)

- Jacketing & Insulation (9)

- Suppliers (8)

- Wiring (8)

- Availability (7)

- Design & Engineering (7)

- Obsolescence Management (7)

- Testing & Prototyping (7)

- Maintenance & Downtime (6)

- Temperature & Fire Resistance (6)

- Enclosures (5)

- Manufacturing (5)

- Circuit Protection (4)

- Data Centers (4)

- Kitting & Fulfillment (4)

- Labeling (4)

- Sensors (4)

- Corrosion (3)

- Datacom (3)

- Cooling & Fans (2)

- Supplier Spotlight (2)

- Automation (1)

- Honeywell (1)

- PLCs (1)

- Relays (1)

- Security (1)

- November 2025 (1)

- October 2025 (1)

- August 2025 (1)

- July 2025 (6)

- June 2025 (4)

- May 2025 (4)

- April 2025 (3)

- March 2025 (11)

- February 2025 (3)

- January 2025 (2)

- December 2024 (1)

- November 2024 (1)

- October 2024 (1)

- September 2024 (3)

- August 2024 (1)

- July 2024 (4)

- June 2024 (3)

- April 2024 (2)

- March 2024 (1)

- January 2024 (1)

- October 2023 (1)

- June 2023 (1)

- May 2023 (1)

- April 2023 (1)

- March 2023 (2)

- October 2022 (1)

- March 2021 (3)

No Comments Yet

Let us know what you think